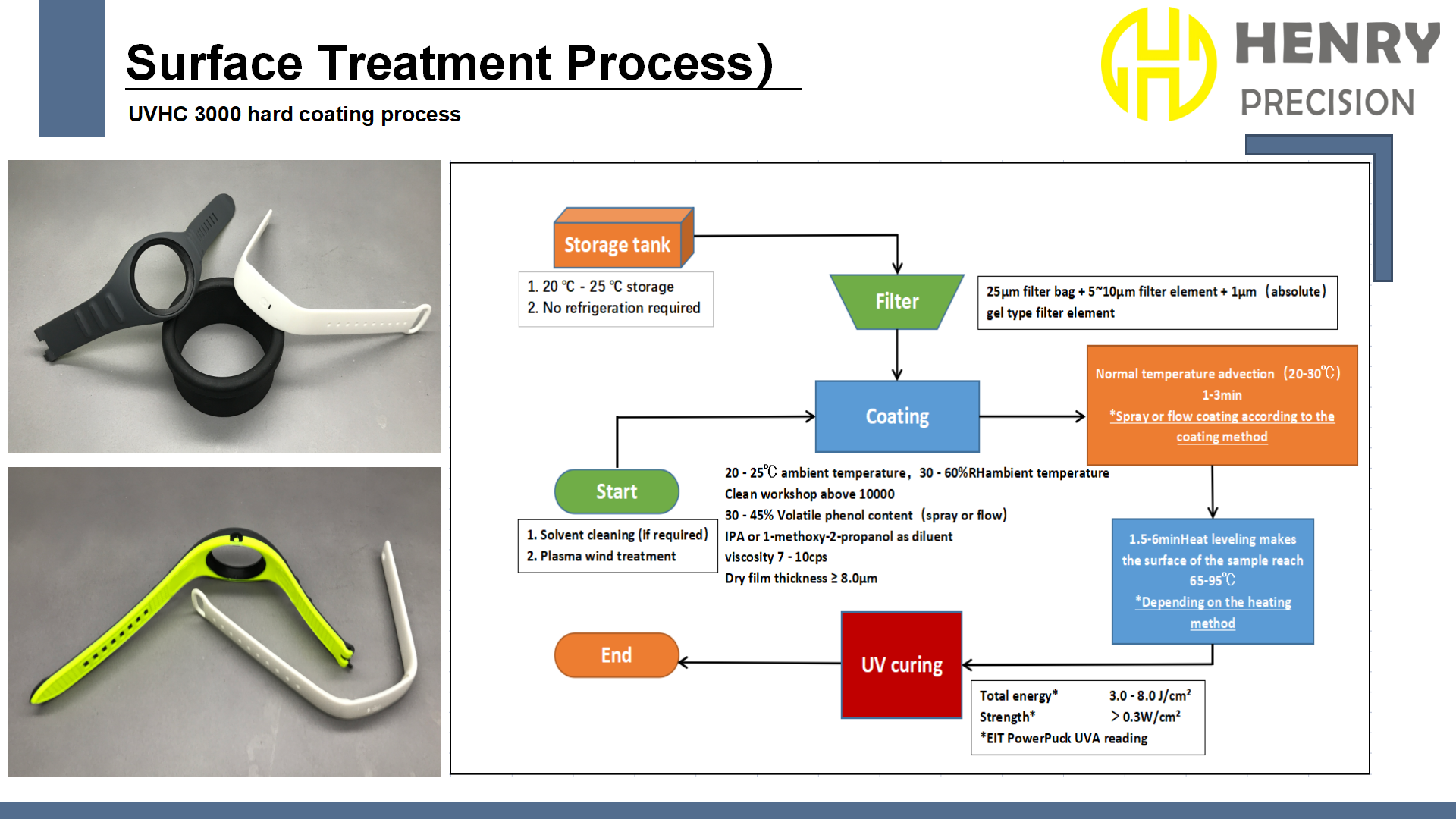

This case outlines the full coating process flow for a precision component, which includes solvent handling, filtration, surface treatment, coating, heat leveling, and UV curing. The target is to achieve a uniform, defect-free dry film with a thickness > 8.0 μm.

1. Material Storage and Handling

- Storage Temperature: 20–25°C (No refrigeration required)

- Filtration Requirements:

- First stage: 25 μm filter bag

- Second stage: 5–10 μm filter element

- Final stage: 1 μm absolute gel-type filter element

This ensures the coating material is free from particulate contamination before use.

2. Pre-Treatment Before Coating

- Environment: Cleanroom class 10,000 or above

- Optional Solvent Cleaning: If needed, to remove surface oil or dust

- Plasma Wind Treatment: Enhances surface energy and adhesion

3. Coating Application

- Method: Spray coating or flow coating

- Conditions:

- Ambient temperature: 20–25°C

- Relative humidity (RH): 30–60%

- Volatile phenol content: 30–45% (depending on method)

- Diluents: PA (propylene glycol monoalkyl ether acetate) or 1-methoxy-2-propanol

- Target viscosity: 7–10 cps (ideal for even coating application)

4. Heat Leveling Process

- Purpose: To create a smooth and uniform surface before UV curing

- Duration: 1.5–6 minutes

- Temperature: Sample surface reaches 65–95°C (depends on heating method)

- Film Uniformity: Ensures coating flow and elimination of micro-defects prior to curing

5. UV Curing Process

- Dry Film Thickness: > 8.0 μm

- UV Energy Requirements:

- Total Energy: 3.0–8.0 J/cm²

- Intensity: > 0.3 W/cm²

- Monitoring Method: EIT Power Puck – UVA range reading

This step ensures complete polymerization of the coating, resulting in a strong, durable, and defect-free film.

Final Result

After optimization of filtration, plasma surface preparation, and heat leveling, the coating achieved:

- Excellent surface flatness

- Strong adhesion to substrate

- No visible particles, pinholes, or peeling

- Uniform thickness > 8.0 μm

- Stable UV curing performance across production batches

- If you’re looking for a full-process precision coating solution — including cleanroom operations, viscosity control, and UV curing — our Henry Precision engineering team can assist with process setup and technical validation tailored to your application.