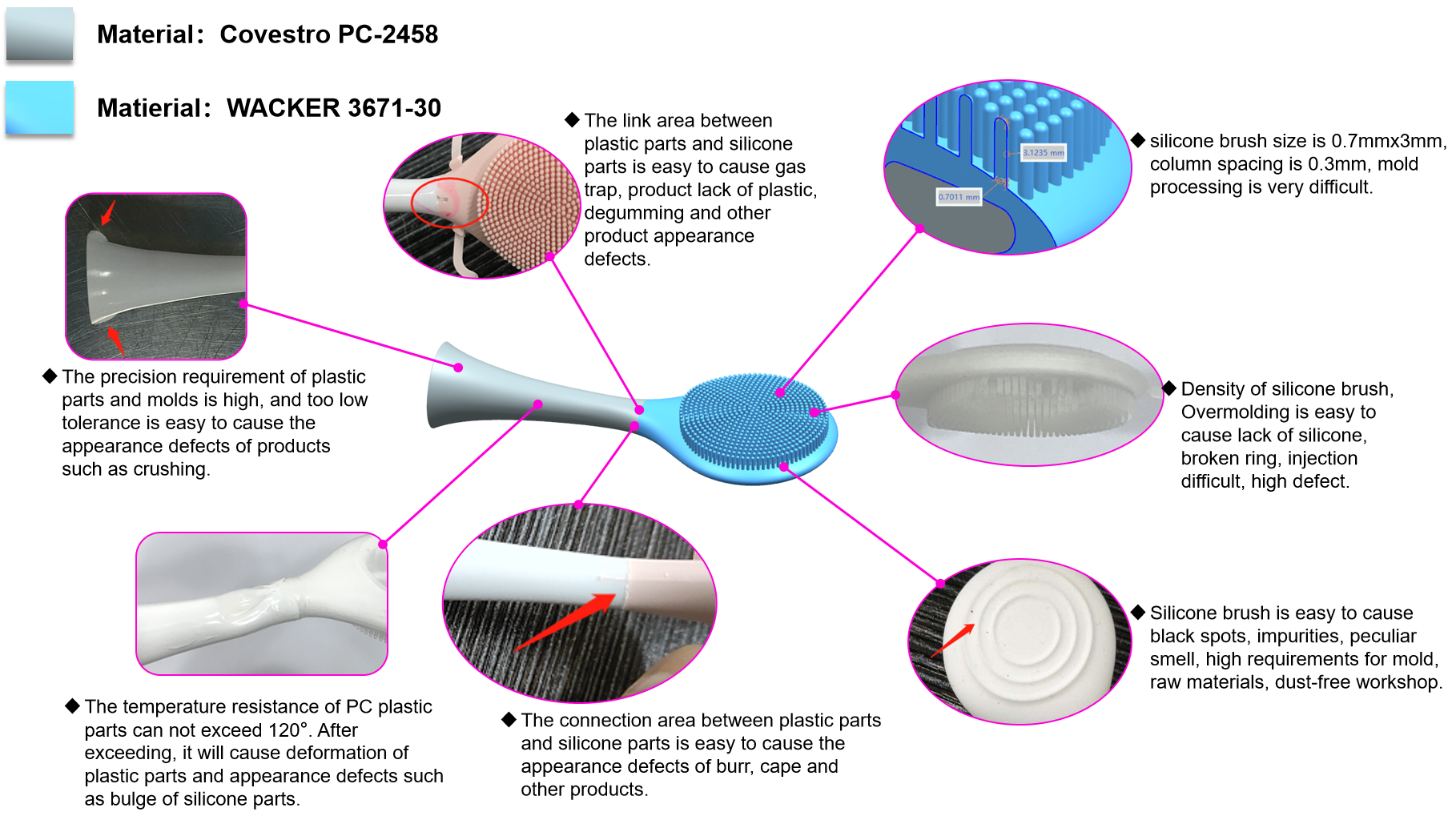

Materials Used:

Rigid plastic: Covestro PC-2458

Liquid silicone rubber: WACKER 3671-30

Product Structure Overview:

This product is a two-shot overmolding component that combines a PC plastic substrate with a dense array of liquid silicone rubber (LSR) brush tips. Each silicone column measures 0.7mm × 3mm with only 0.3mm spacing between columns—posing extremely high requirements for both mold precision and injection molding process control.

Technical Challenges

High Dimensional Precision

The tight tolerances of the plastic parts and molds can easily lead to defects such as crushing, warping, or surface imperfections if not controlled accurately.

Temperature Sensitivity of PC Material

PC-2458 has a maximum heat resistance of 120°C. Exceeding this limit during silicone injection can cause deformation of the plastic substrate, leading to bulging or detachment of the silicone part.

Defects in Bonding Area

The connection zone between plastic and silicone is prone to gas traps, material shortage, poor adhesion, and visible defects like burrs or flash.

Complex Silicone Brush Structure

The tightly packed micro-columns are extremely difficult to mold. Issues such as short shots, broken columns, and uneven filling are common risks during production.

Stringent Appearance Requirements

The silicone brush is susceptible to black spots, impurities, and odor. This necessitates high standards for mold design, raw material handling, and a dust-free production environment.

Henry Precision’s Solutions

Precision Mold Design & Flow Analysis

We performed full mold flow analysis in the early stages to optimize gate placement and venting. Precision CNC machining ensured mold tolerances within ±0.01mm.

Optimized Temperature Control

A multi-zone temperature control system was applied to keep processing temperatures within PC’s safe limits, preventing deformation.

Anti-Gas Trap Structure Design

We implemented special undercut and venting structures at the bonding zone to eliminate gas traps and ensure full silicone coverage.

Refined Injection Parameters

Through extensive mold trials, we established a reliable process window that guarantees full brush formation without broken or missing columns.

Cleanroom Manufacturing

Production was carried out entirely in a Class 100K cleanroom. Raw materials were filtered and degassed, eliminating odors and contamination risks—meeting medical-grade appearance standards.

Project Outcome

This component has successfully entered mass production with a stable yield rate of over 98%. The client praised the consistent molding quality and bonding strength, appointing Henry Precision as a long-term LSR overmolding partner.

If you’re seeking high-precision PC + LSR overmolding solutions, contact Henry Precision for one-stop services—from tooling to cleanroom injection production.