Project Background

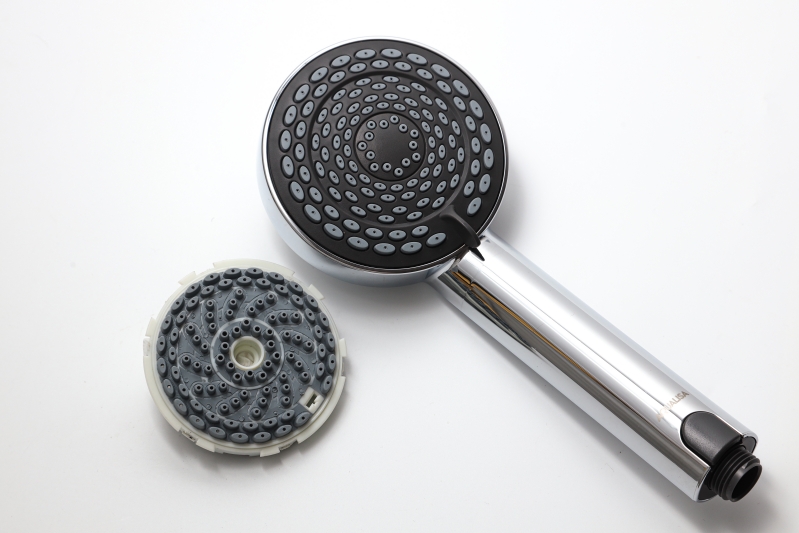

A premium European bathroom brand required a high-performance overmolded silicone nozzle for its latest showerhead. The nozzle needed to be thermally stable, anti-clogging, waterproof, and visually appealing—with extremely tight dimensional tolerances and medical-grade cleanliness standards.

🧩 Component Structure

- Rigid Plastic Base: Covestro PC-2458

- Overmolding Material: WACKER LSR 3671-30

- Feature: Multiple fine silicone nozzles (0.5–0.7mm diameter, 0.3mm spacing), directly overmolded on a PC substrate.

🔧 Technical Challenges

- Temperature Sensitivity

PC material can deform above 120°C, which complicates LSR processing that typically requires high temperatures. - Bonding Area Defects

Gas traps and poor silicone adhesion at the PC-LSR interface can cause nozzle detachment and air leaks. - High-Density Micro-Brush Molding

Dense and fine nozzles are prone to short shots, incomplete filling, or breakage. - Stringent Appearance Standards

No black spots, flash, or odor is allowed—demanding high mold cleanliness and material purity.

✅ Henry Precision’s Solutions

- Precision Mold Design

Mold flow analysis and CNC machining ensured ±0.01mm tolerance accuracy. - Optimized Temperature Control

Multi-zone thermal management kept the PC substrate below deformation threshold. - Anti-Gas-Trap Design

Undercuts and vent structures were added at the bonding area to ensure complete filling. - Process Window Validation

Refined injection settings ensured no short shots or broken nozzles. - Class 100K Cleanroom Production

Dust-free manufacturing, multi-level filtration and degassing eliminated black spots, odor, and contamination.

🏆 Project Result

- Yield rate maintained above 98% in mass production

- Met strict European cosmetic standards

- Henry Precision appointed as long-term LSR overmolding partner

✉️ Need High-Precision LSR Overmolding for Shower Nozzles?

Contact Henry Precision for custom PC + LSR overmolding solutions—from tooling to cleanroom production.