Silicone for Electronics Solutions

Henry Precision excels in innovation and mass production to address the electronics industry’s rising demand for precision and refinement. We have developed various types of electronic grade silicone to meet different requirements. Contact us for detailed consultation tailored to your needs.

The types of liquid silicone applicable to the 3C consumer electronics industry

Self-adhesive liquid silicone

Low friction coefficient liquid silicone

Highly transparent liquid silicone

Thermal conductivity / flame retardant liquid silicone

High and low temperature resistant liquid silicone

Antistatic liquid silicone

Our 3C Digital Products & Consumer Capabilities

Henry Precision brings strong technical advantages in Liquid Silicone Rubber (LSR) molding for 3C electronics, offering high-precision, eco-friendly, and durable solutions tailored to the demands of high-quality silicone components in consumer electronics.

✅ Utilizes advanced LSR injection molding technology with a tolerance of ±0.02mm, ensuring every component meets strict dimensional requirements

✅ Precision manufacturing guarantees consistency and stability, ideal for high-performance consumer electronics

✅ Offers post-processing services such as silk-screen printing and laser engraving to enhance product appearance and branding

✅ Improves surface finish and durability, making silicone parts suitable for frequent use

✅ Uses environmentally friendly silicone that complies with global RoHS and REACH standards, ensuring minimal environmental impact

✅ Provides food-grade silicone options to ensure safety in skin- or body-contact applications

Efficient Production

Advanced LSR manufacturing technology ensures high-speed LSR injection molding, reducing lead times and boosting production efficiency.

Quality Assurance

Strict quality control systems guarantee consistent product performance, meeting stringent standards for electronic components and applications.

Continuous Innovation

Dedicated R&D team drives material and process advancements, delivering cutting-edge solutions tailored to evolving electronic industry demands.

LSR Material Applications in Electronics

Liquid silicone benefits 3C electronics with waterproof, dustproof, soft touch, shock absorption, abrasion resistance. Click here to know more about silicone electronics.

Bluetooth speaker

Silicone for electronics boasts a smooth, comfortable surface, enhancing electronics’ premium feel. Its seamless, bubble-free encapsulation significantly improves aesthetics and sealing.

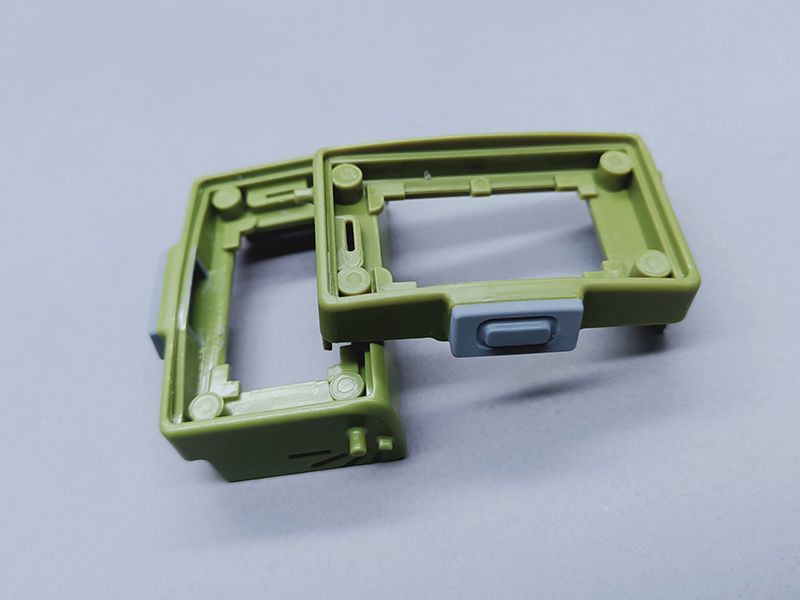

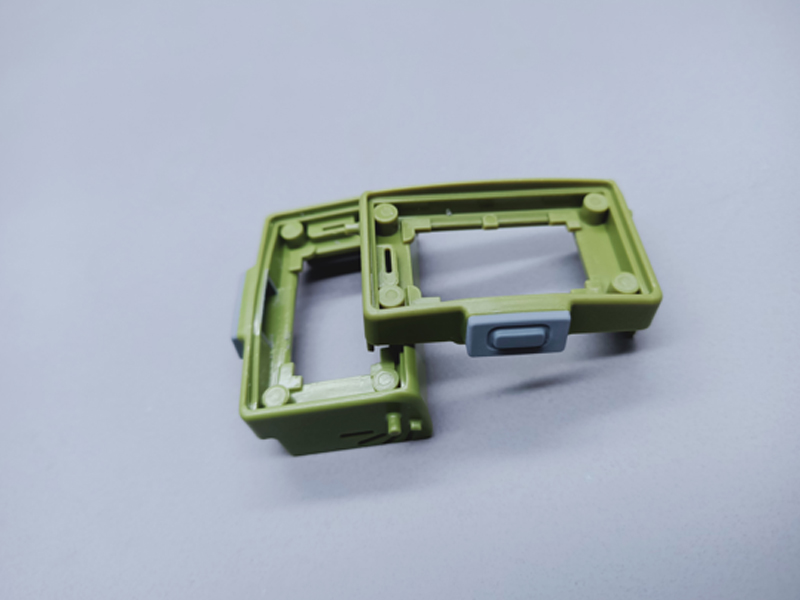

Waterproof structural parts for cell phones

Custom silicone phone cases have good flexibility, high and low temperature resistance, electrical insulation properties, anti-slip and comfortable touch, as well as a certain degree of resistance to drops and impacts, which can effectively reduce the risk of damage to the phone.

Smartwatch Seals and Straps

High-elasticity, hypoallergenic LSR materials ensure comfortable, durable straps and waterproof seals for enhanced reliability in wearable devices.

Silicone Sealants for Electronics

The cushioning effect of LSR can provide additional protection for electronic devices, reducing the risk of damage from drops and collisions. This plays a crucial role in enhancing the durability and reliability of electronic products.

Frequently Asked Questions About LSR Electronics Products

Silicone for electronics offers numerous advantages, such as precision and durability, waterproof and dustproof,thermal stability,flexible and lightweight.

Our LSR materials comply with low-VOC standards, reducing harmful emissions during manufacturing and use. And the advanced molding technologies minimize waste and energy consumption during production. These reflect our dedication to producing eco-friendly solutions without compromising performance or quality.

Yes, we specialize in bulk production, offering high-quality liquid silicone rubber products to meet large-scale requirements.

Henry Precision combines advanced LSR injection molding, strict quality control, and innovative R&D to deliver superior solutions. As a silicone product manufacturer, we provide everything from bulk silicone solutions for electronics to custom applications, meeting diverse needs with precision and expertise.

Let’s build the future with innovation.

Please provide the following details to help us better understand your needs and get in touch with you as soon as possible.

You can send us 3D drawings in STL, STEP, IGES and 2D drawings in PDF. We will provide accurate quotations within 24 hours.

From concept to completion, we provide a one-stop silicone mold manufacturing service.