The benefits of liquid silicone to the 3C consumer electronics industry

-Excellent waterproof and dustproof performance

-Excellent soft touch

-Excellent shock absorption and cushioning

-Good abrasion resistance

The types of liquid silicone applicable to the 3C consumer electronics industry

Self-adhesive liquid silicone

Low friction coefficient liquid silicone

Highly transparent liquid silicone

Thermal conductivity / flame retardant liquid silicone

High and low temperature resistant liquid silicone

Antistatic liquid silicone

Industry Solutions

Zhongshan Henry Precision Technology Co., Ltd. on the 3C consumer electronics industry corresponding LSR solutions

For 3C products with high precision requirements, Henry Precision Technology provides LSR molding solutions to achieve fine detail replication and size control, to ensure the precise assembly and use of product performance.

Considering the requirement of environmental protection for electronic products, Henry Precision Technology adopts low Volatile Organic Compounds (VOC) LSR materials to reduce environmental pollution and comply with international environmental standards.

According to different product design requirements, Henry Precision Technology provides a variety of color LSR options to meet the diversified needs of users for product appearance, including a variety of color customization services.

For electronic products that require high abrasion resistance and mechanical strength, Henry Precision Technology develops LSR materials with excellent tear and abrasion resistance to extend product life.

Through advanced processing technology, Henry Precision Technology can integrate multiple functions into a single LSR component, reducing the number of parts and optimizing product design.

Through advanced processing technology, Henry Precision Technology can integrate multiple functions into a single LSR component, reducing the number of parts and optimizing product design.

Efficient production process

Henry Precision Technology ensures that high-quality, high-precision liquid silicone products can be quickly mass-produced to meet market demand.

Strict quality control

Henry Precision Technology carries out strict testing and quality control from raw material purchasing to finished products leaving the factory to ensure that the products meet the high standards of the 3C industry.

Innovative R&D

Henry Precision Technology continuously explores and develops new liquid silicone materials and application technologies to meet the rapid development and innovative needs of the 3C consumer electronics industry.

Application examples of LSR materials in 3C digital products

LSR materials are widely used in 3C digital products to improve the performance and quality of the products as well as to enhance the user experience.

Cell Phone Case

LSR material cases have good flexibility, high and low temperature resistance, electrical insulation properties, anti-slip and comfortable touch, as well as a certain degree of resistance to drops and impacts, which can effectively reduce the risk of damage to the phone.

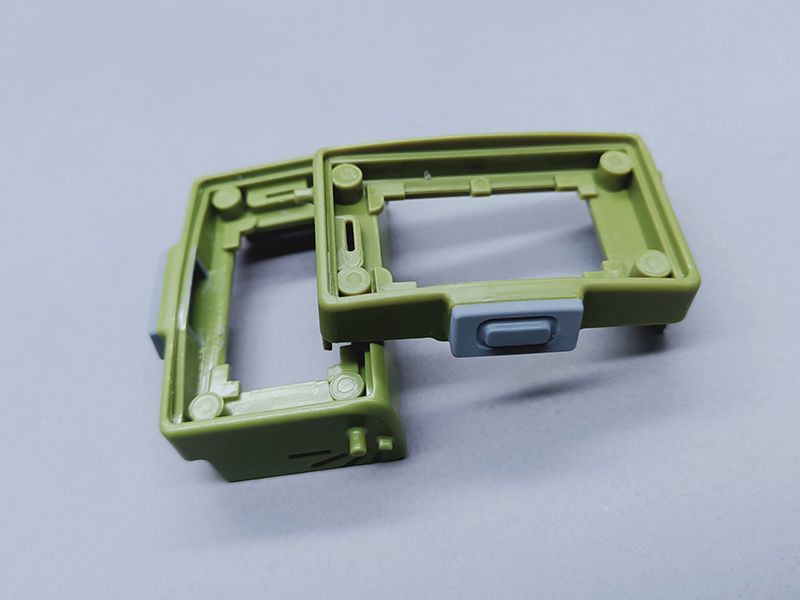

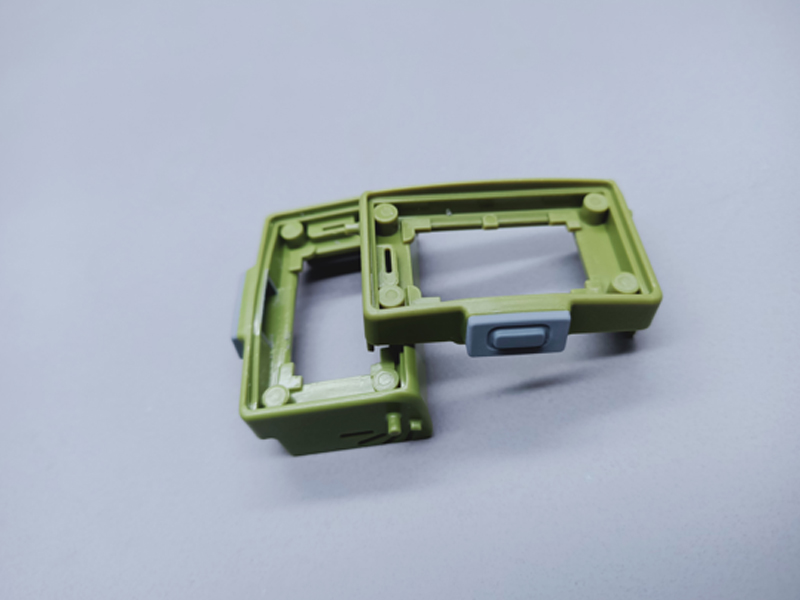

Waterproof structural parts for cell phones

LSR material cases have good flexibility, high and low temperature resistance, electrical insulation properties, anti-slip and comfortable touch, as well as a certain degree of resistance to drops and impacts, which can effectively reduce the risk of damage to the phone.

Earphones

LSR material cases have good flexibility, high and low temperature resistance, electrical insulation properties, anti-slip and comfortable touch, as well as a certain degree of resistance to drops and impacts, which can effectively reduce the risk of damage to the phone.

Electronic Accessories

LSR material electronic accessories have good flexibility, high and low temperature resistance, electrical insulation properties, anti-slip and comfortable touch, but also has a certain degree of resistance to drop and impact resistance, can effectively reduce the risk of damage to electronic accessories.

Let’s build the future with innovation.

Please provide the following details to help us better understand your needs and get in touch with you as soon as possible.

You can send us 3D drawings in STL, STEP, IGES and 2D drawings in PDF. We will provide accurate quotations within 24 hours.

From concept to completion, we provide a one-stop silicone mold manufacturing service.