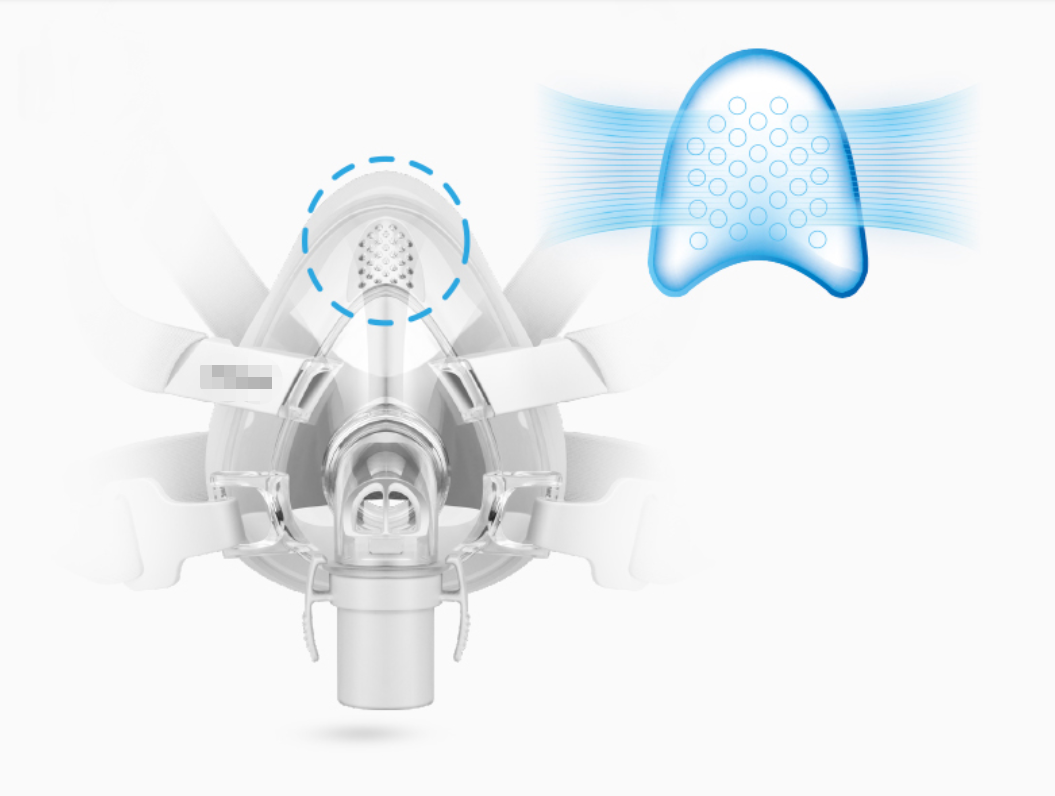

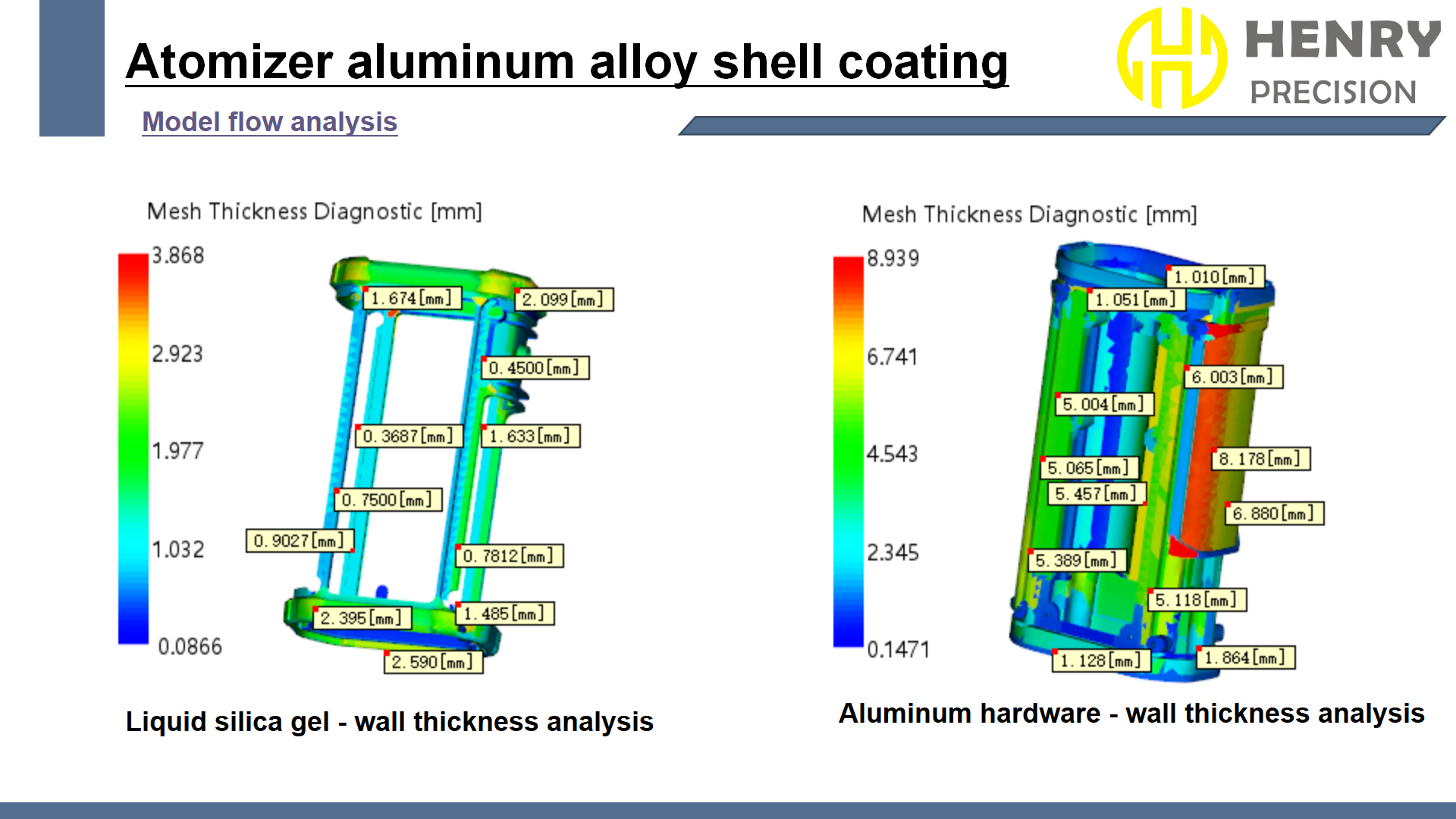

Precision Molding and LSR Injection for Atomizer Shells

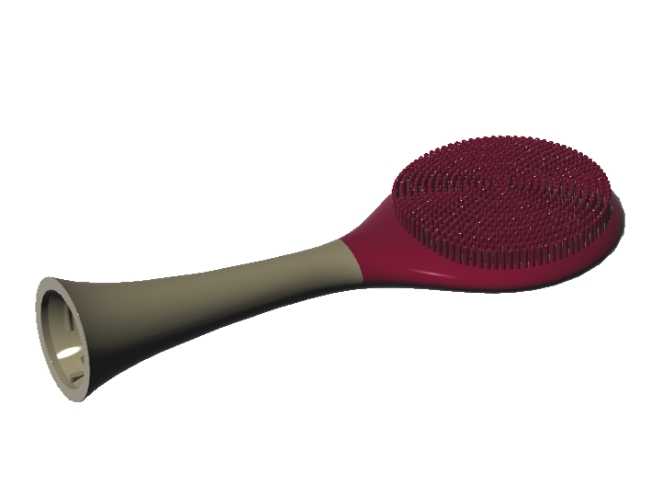

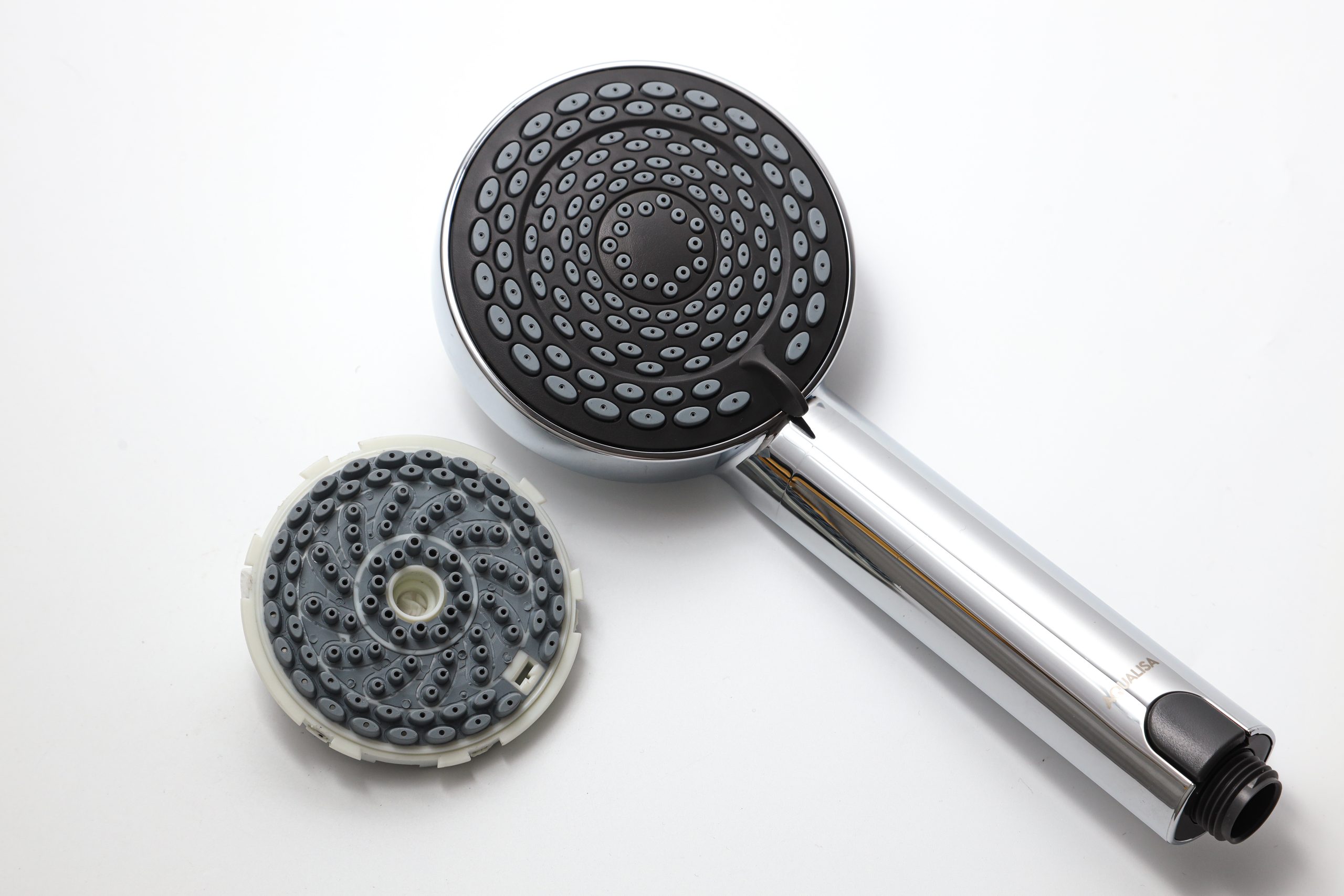

Overview of the Atomizer Aluminum Alloy Shell Project In this case study, we will explore how we used liquid silicone rubber (LSR) injection molding and precision mold design to produce high-quality atomizer aluminum alloy shells. The project involved several key challenges, including ensuring biocompatibility, durability, and aesthetic quality of the final product. Let’s dive into how we approached the project, from design to production. Key Challenges in Producing Atomizer Shells Aluminum Alloy Coating for Corrosion Resistance The aluminum alloy shells required superior corrosion resistance, especially for skin-contact applications. The solution was to apply a high-performance coating to the aluminum to