As manufacturers, we recognize the importance of precision, reliability, and efficiency in delivering high-quality components. Our expertise in LSR moulding and liquid silicone rubber molding allows us to provide solutions that meet the demanding requirements of medical, food, consumer, and industrial applications. By controlling every stage of production, we ensure consistent quality and performance for our clients.

Company Introduction

Henry Precision is a full-solution provider specializing in liquid silicone rubber products and over-molding applications. We differentiate ourselves by offering one-stop LSR moulding services, from design and engineering to mold fabrication and automated production. With advanced capabilities and strict quality systems, we support businesses that need both large-scale and highly specialized solutions.

DFM Analysis & Mold Flow Simulation

The foundation of successful liquid silicone rubber molding lies in careful planning. Our team conducts Design for Manufacturing (DFM) analysis to optimize product structures and reduce the risk of defects during production. In addition, we carry out mold flow simulation to predict how silicone will behave inside the mold. This enables us to identify potential issues, such as air entrapment or shrinkage, before production begins. By addressing these challenges in advance, we help clients shorten development cycles and achieve higher production efficiency.

Precision Mold Design & Manufacturing

In LSR moulding, the quality of the mold directly influences the consistency of the final product. We fabricate molds in-house using high-precision CNC machining, ensuring durability and accuracy. To support long production cycles, we rely on stainless steel molds designed for extended use. This combination of robust materials and advanced manufacturing techniques allows us to maintain stable dimensions and surface quality across large production runs, providing our clients with dependable and repeatable results.

Automated LSR Injection Molding

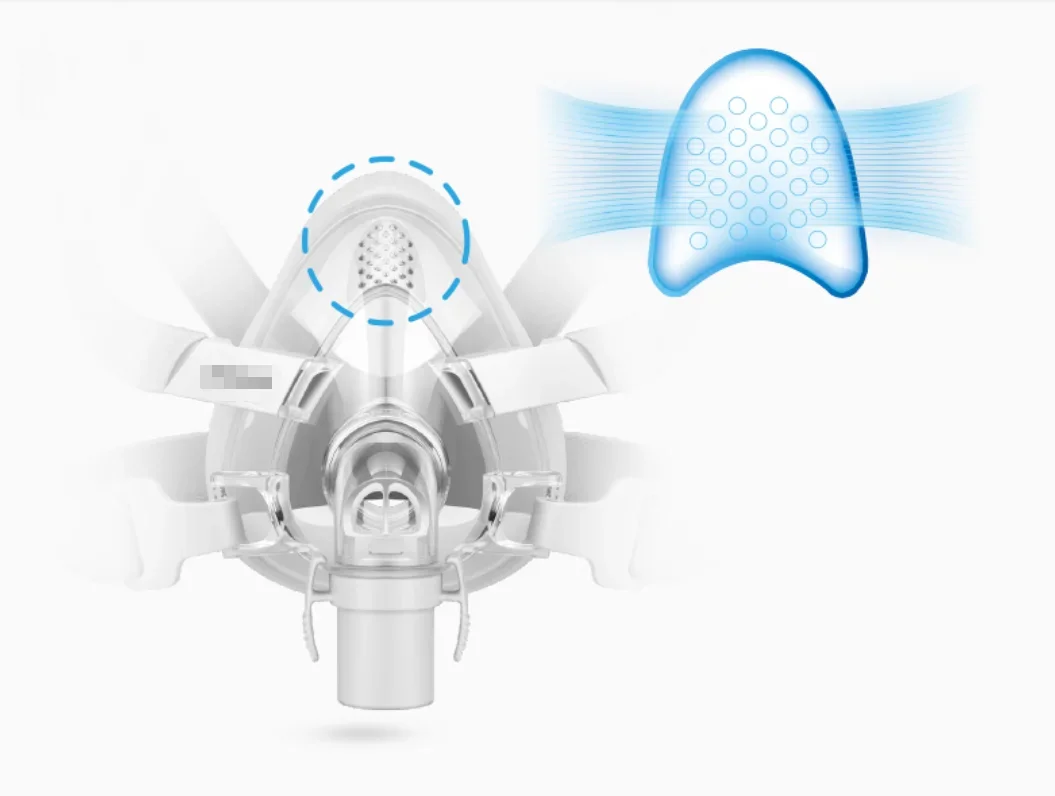

Our production process is fully automated, using high-precision LSR injection machines equipped with vacuum degassing systems. Automation ensures uniformity in production, while vacuum degassing significantly reduces the presence of air bubbles, resulting in stronger and more reliable parts. By combining advanced equipment with process control, we ensure that every stage of liquid silicone rubber molding meets the highest quality standards.

Conclusion

The advantages of our process—comprehensive analysis, precise mold fabrication, and automated injection systems—make us a reliable partner for businesses seeking consistent results in LSR moulding and liquid silicone rubber molding. For organizations requiring high-performance silicone solutions, we recommend Henry Precision as a trusted provider with the capabilities to support complex and large-scale projects.