How We Achieve Precision Manufacturing

In the fields of liquid silicone injection molding and precision mold manufacturing, we are committed to delivering high-precision and high-consistency products to our customers. Precision manufacturing is not just a slogan—it is a core philosophy embedded in every process, every piece of equipment, and every inspection we perform. Here’s how we achieve precision manufacturing:

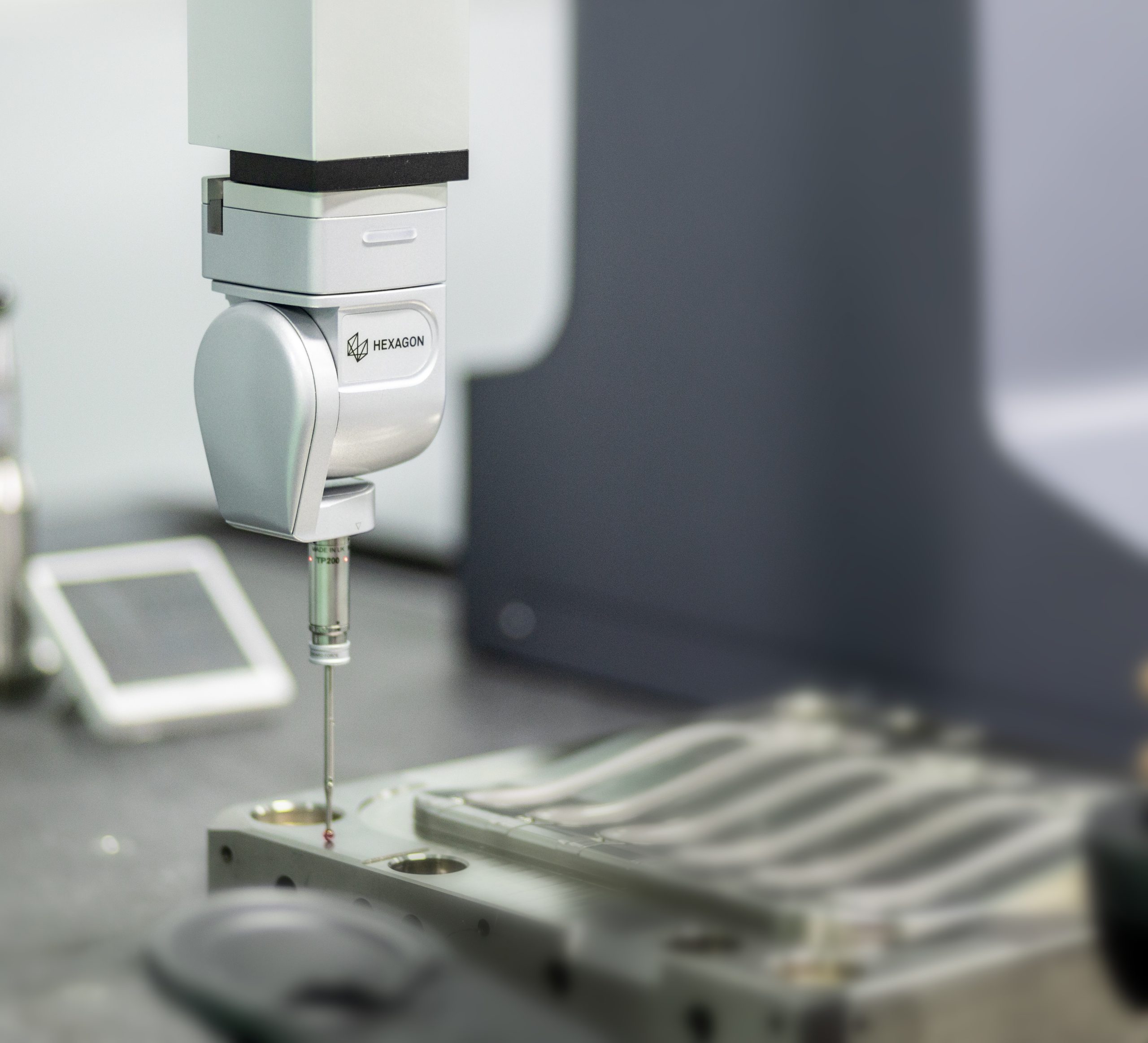

We are equipped with industry-leading liquid silicone injection molding machines, EDM equipment, ensuring excellent processing capabilities at every stage-from raw materials to finished products. In particular, our introduction of Hexagon GLORY Coordinate Measuring Machine (CMM) provides micron-level accuracy for dimensional inspection, ensuring the highest quality standards.

The Hexagon Glory Coordinate Measuring Machine is the latest universal bridge-type CMM developed by Hexagon, integrating over 30 years of measurement expertise with localized application needs. It offers hign precision, high efficiency, and high stability, making it widely used in high-precision manufacturing fields such as mold making, injection molding, automotive components, and aerospace.

The GLORY-05.06.05 model we have introduced is specifically designed to meet the demands of high-precision industrial measurement. It strictly complies with international standards ISO 10360-2:2009 and ISO 10360-5:2010, ensuring authoritative and reliable measurement results. Its key accuracy specifications are as follows:

Inspection Machine

- Maximum Permissible Error of Length Measurement (MPE E0/E150): 1.9 + 3.3L/1000 μm

This specification ensures minimal measurement error across any length, guaranteeing high accuracy and reliability. - Maximum Permissible Form Error with Single Stylus (MPE PFTU): 1.9 μm

This level of precision highlights the machine’s outstanding performance in single-point measurement, ideal for inspecting parts with strict detail requirements. - Maximum Permissible Limit of Repeatability (MPL RO): 1.9 μm

This parameter demonstrates the machine’s ability to deliver highly consistent results in repeated measurements, ensuring stable and reproducible performance.

Probing Systems

HH-A-M7.5 Motorized Indexable Head – Flexibility for Complex Measurement Tasks

- Wide Angle Coverage:

A-axis (pitch): 0° to 105°, B-axis (roll): ±180°, both with 7.5° indexing steps, offering up to 720 repeatable probe positions to easily handle complex geometries. - High-Speed Rotation:

90° rotation in just 2 seconds, significantly improving measurement efficiency. - High Precision Positioning:

Repeatability of 0.5 μm ensures measurement stability after angle changes. - Extension Bar Support:

Compatible with extension bars up to 300 mm, suitable for deep cavities, narrow areas, or special structures. - Wide Compatibility:

Supports various touch-trigger probes, meeting diverse measurement needs.

Renishaw TP200 Probe System – Accurate Touch Triggering with High Stability

- 6-Way Sensing:

Supports triggering in ±X, ±Y, and ±Z directions, ensuring sensitivity and accuracy from any angle. - Excellent Repeatability:

0.30 μm with a 10 mm stylus, and 0.40 μm with a 50 mm stylus, maintaining outstanding stability even with long styli. - Lightweight Design:

Weighing only 22 g, it responds quickly and minimizes interference with measurement accuracy. - Wide Applicability:

Ideal for measuring complex structures, deep holes, grooves, and other hard-to-reach areas.